Coating Systems

THE ADVANTAGES OF THERMAL INSULATION

To achieve all the objectives indicated by the ID 26/06/15 "Minimum requirements", indicating the minimum thermal performance values of buildings, great attention must be paid to making the right technical choices and using The right materials to obtain ideal thermal insulation. The achievement of a good thermal insulation is essential to obtain a good level of comfort and a consequent economical saving for the management of the winter heating and the summer cooling.

TYPES OF THERMAL INSULATION

• Insulation of the walls from inside the rooms

This type of insulation allows to keep the external architectural features, unchanged. it is more economical because it does not need scaffolding and it is certainly the best solution for buildings for non-constant use. The main defect, however, of this type of insulation, consists in the fact that it needs a careful hygrometric verification to not create or aggravate the phenomena of condensation inside the masonry; It reduces the useful volume of the room and therefore the habitable space, forcing the adaptation of electrical systems for heating.

• Insulation of the cavity

It is inserted between a wall of external cladding of greater size and an internal wall of aminor section in which the insulating material is interposed, normally in rigid slabs, but also bulk granules can be used. This type of system increases the thermal inertia of the building compared to the previous case but it is not possible, with this technique, to eliminate the thermal bridges and the consequences connected to them.

• Insulation from outside

Isolating the walls from the outside (thermal insulation to coat) reduces the dispersion and increases the capacity of thermal storage of the building. The walls heat up, accumulate warmth and then return it to the environment. This means that heating and cooling systems can operate less than a total number of hours, saving energy and reducing polluting emissions. A sure advantage of the insulation is the total elimination of thermal bridges, that is, those critical points (angles, pillars and beams inserted in the masonry) where it is easier to experience phenomena of formation of mould and stains. It is ideal when renovation works of the building facades are necessary, since by placing in thermal quietness the existing structure avoids the physical stresses due to thermal escape and prevents the formation of new cracks. The thermal insulation system is the most viable solution for the immediate improvement of the energy performance of an existing building and allows, from the start, a saving of CO2 emissions in the environment.

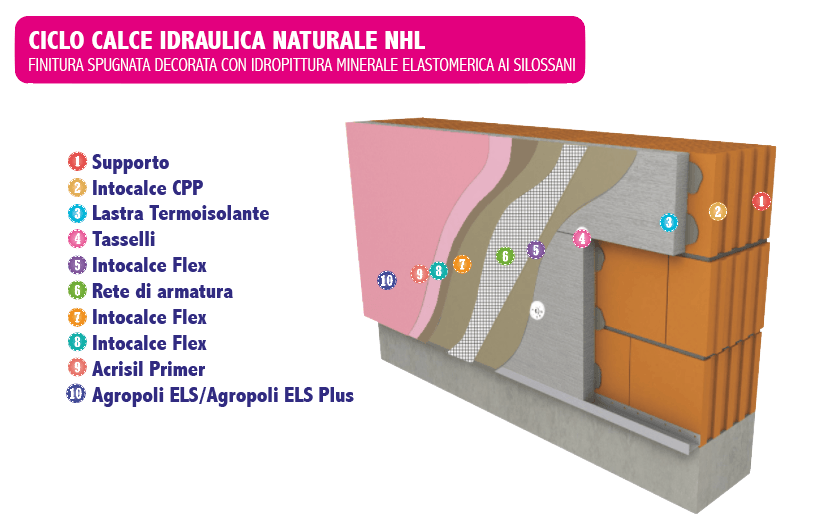

Coating Construction Systems

Thermal insulation is a process that allows the insulation of the walls of a building from the outside, in a simple way, both on buildings of new construction and on existing buildings, without disturbing the residents and totally eliminating those points of the structure in which there are preferential ways for the dispersion of heat.

• Energy Saving and future

Saving on consumption is undoubtedly the safest and most environmentally friendly form of energy production. It does not contribute to the increase of the overheating of the atmosphere, it is economical, advantageous and always available. A thermal insulating coat reduces the consumption of primary energy – proportionally to the thickness of insulation – thus decreasing CO2 emissions. A low consumption house, or even an "energetically passive" house, with insulating thicknesses that allow high thermal insulation values, reduces heat dispersion to the lowest levels. With the coat, it becomes simple to meet the European energy criteria that will bring in a few years to realize only residential buildings in energetic equilibrium, that is that they do not consume more energy than they produce.

• Living Comfort

The comfort in inhabited environments depends mainly on the difference in temperature between the air and the surfaces of the walls. If the difference is too high, convective motions in the internal air may occur. The difference in temperature between the rooms and the walls that surround them should not exceed 3°c, to have a comfortable and healthy living environment. The coat prevents energy dispersions outwards, allowing the walls to become heat reserves for the best living comfort. Thermal insulation prevents the problems and defects linked to the presence of condensation moisture (i.e. the formation of moulds and dark spots). These problems can occur if the inner surface of the walls is too cold, even in certain places. Therefore all insulation should be placed on the outer surface of the walls. In fact, with this solution all the housing of the building is kept warm in a uniform way, without creating temperature gradients between the different zones.

• Advantages in summer

The savings on heating costs, the elimination of thermal bridges, the comfort of living when outside is cold are the first things that come to mind when cladding is mentioned. But not everyone knows that the thermal insulating systems, applied on masonry walls, allow the improvement of the performance of a building in summer. The insulating layer located outside the building filters out the energy and reduces its passage through the wall preventing it from overheating excessively, and quickly. The effect is to have fresh interior walls during the day and thus be able to use the cool of the night to rest satisfactorily. The improvement of the periodic transmittance of the walls, which is obtained with the application of a coat on the external masonry, allows the improvement of both the displacement of the heat wave, and to weaken its intensity. Today, thanks to the high standards of quality of life, we expect from a building that the internal climate is always suitable for our needs and our wellbeing. The lifestyle of our industrialised society leads us to spend more than 90% of our time in air-conditioned environments, residences, workplaces, activities and/or recreation. To guarantee the comfort in every type of building is essential to start from a correct design, defining the requirements to be imposed on the envelope and choosing the design parameters that add value to the living. Defined these requirements, we proceed to identify the technological solutions best suited to guarantee them, making them compatible with the existing architectural and economic constraints.

Construction systems and Living comfort

Malvin has worked in this regard through the experimentation and the creation of innovative and specific constructive systems for the resolution of these problems. We offer a new range of products, born from studies and experimentation in our research and development laboratories and from direct experience in the yard, for the creation of thermal insulating coats not only of high quality and durability but also of easy and fast Application. For the attainment of the best living comfort and the respect of the values imposed by the regulations regulating the thermal insulation ID 26/06/15 "Minimum requirements" is therefore the "Malvin construction system", which provides a series of solutions that are Innovative, safe and of durable construction.

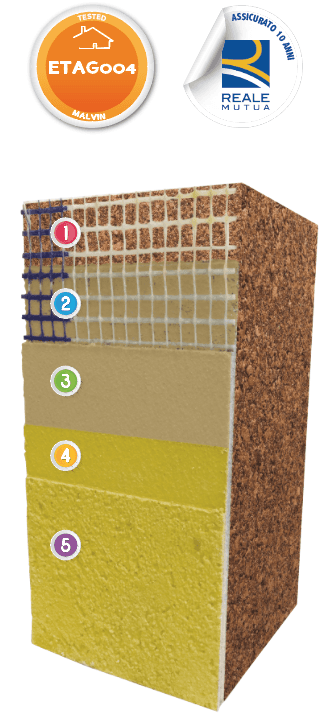

Coat system with natural cork cladding

System with insulating panels in natural cork adhesive, Natural Hydraulic lime and acryl-siloxane decoration

Strengths

• Certified System

• System Insured 10 years

• Guaranteed Performance

• Durability

• Environmentally friendly

• Natural 100%

• Reduction of energy consumption

• Insulation from cold and heat

• Correction of thermal bridges

• High thermal and acoustic insulation

• High breathability

• Sound absorbing

• Good thermal inertia

• Energy Requalification

• Energy saving

• Thermo-Hygrometric Comfort

• Healthier and livable Environments

• Improvement of living comfort

• Ease and speed of application

1-Cork Plate kPa ≥ 270-λ ≤ 0.041 W/MK

2-Glass Fibre reinforcement net ETAG 004

3-Intocalce CPP adhesive/rasante Natural Hydraulic lime (NHL)

4-Acrisil Primer coloured Acril-siloxane

5-Acrisil coloured mineral coating acril-Siloxane

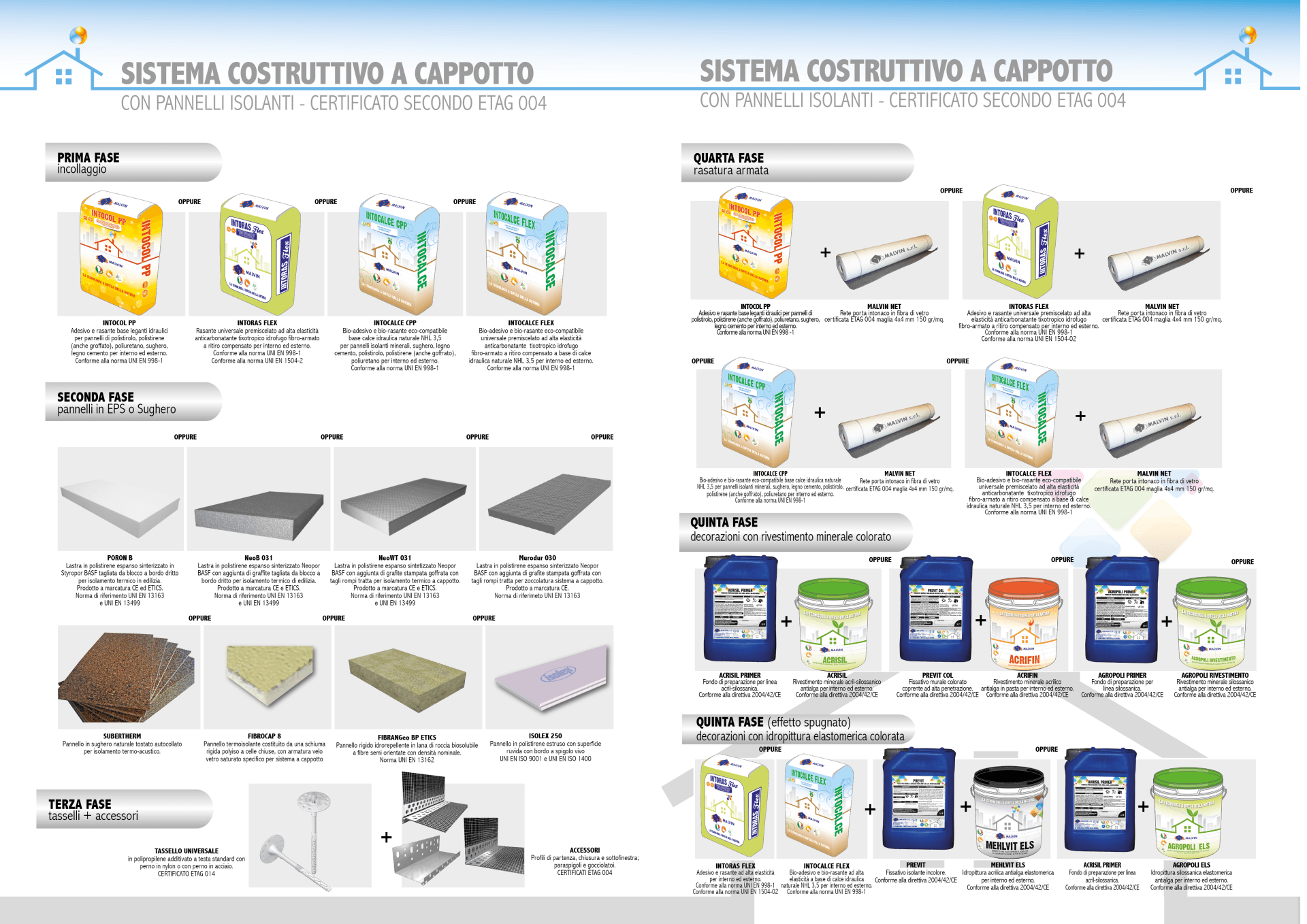

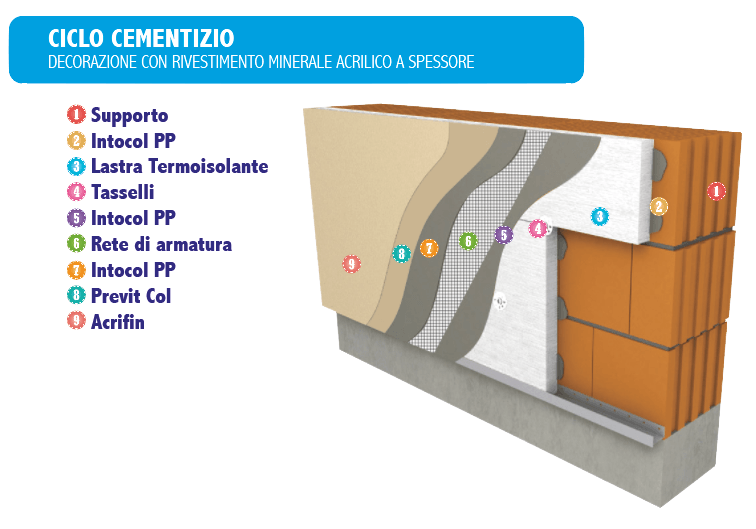

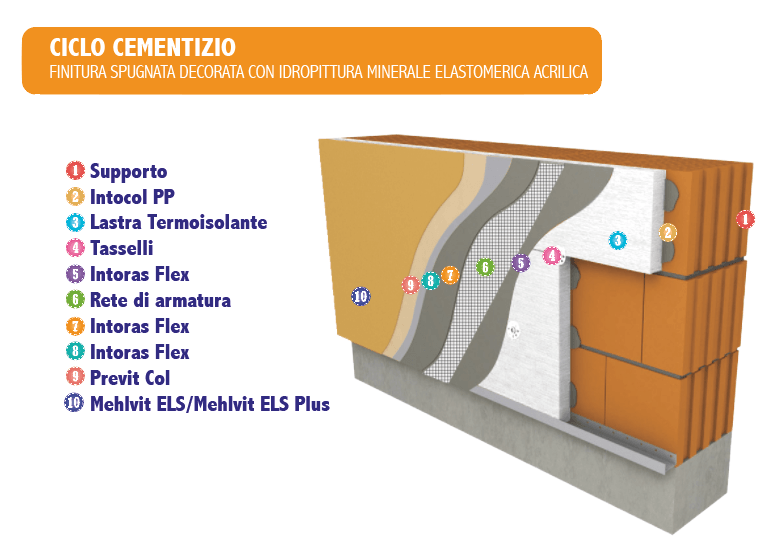

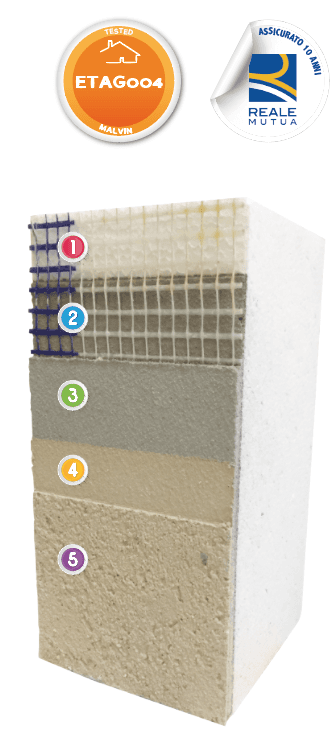

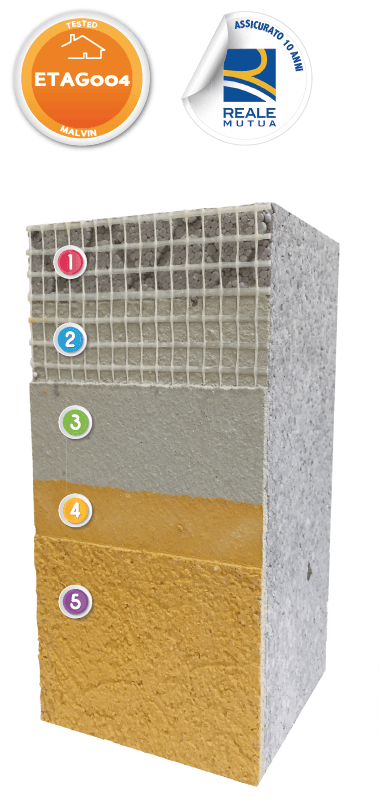

COAT SYSTEM WITH WHITE EPS SHEET

Systemwith insulating panels in White EPS

Cement adhesive / smoothing agent

Acrylic mineral decoration

STRENGTHS

• Certified system

• System guaranteed for 10 years

• Guaranteed services

• Durability

• Reduction of energy consumption

• Insulation from cold and heat

• Thermal bridge correction

• High thermal and acoustic insulation

• Energy requalification

• Energy saving

• Thermo-hygrometric comfort

• More healthy and livable environments

• Improvement of living comfort

• Facility and speed of application

1-White EPS plate kPa ≥ 100/150-λ ≤ 0.035/0,036 W/MK

2-Glass Fibre reinforcement net ETAG 004

3-Intocol PP adhesive/Smoothing Hydraulic Binders

4-Previt with acrylic coloured PRIMER

5-Acrifin coloured acrylic mineral coating

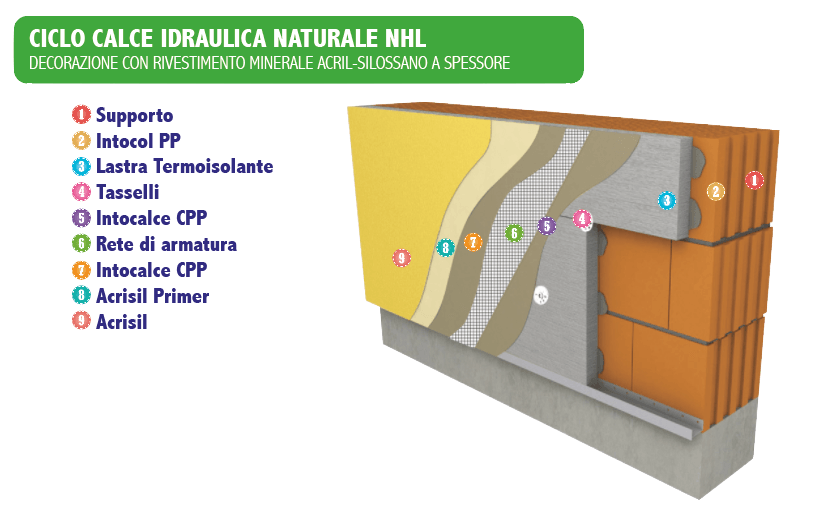

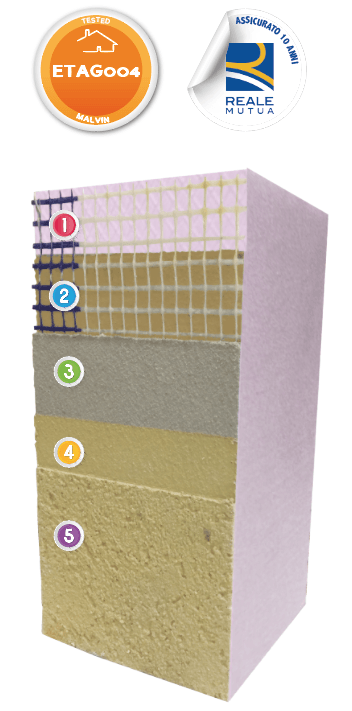

Coat system with EPS sheet Thermo-reflective grey with graphite

System with insulating panels in EPS with graphite

Adhesive/Smoothing Natural hydraulic lime in NHL

Mineral decoration Acril-siloxane

Strengths

• Certified System

• System Insured 10 years

• Guaranteed Performance

• Durability

• Environmentally friendly

• Reduction of energy consumption

• Insulation from cold and heat

• Correction of thermal bridges

• High thermal and acoustic insulation

• Energy Requalification

• Energy saving

• Thermo-Hygrometric Comfort

• Healthier and livable Environments

• Improvement of living comfort

• Ease and speed of application

1-Grey EPS sheet with graffite kPa ≥ 100/150-λ ≤ 0.031 W/MK

2-Glass Fibre reinforcement net ETAG 004

3-Intocalce CPP adhesive/rasante Natural Hydraulic lime (NHL)

4-Acrisil Primer coloured Acril-siloxane

5-Acrisil coloured mineral coating acril-Siloxane

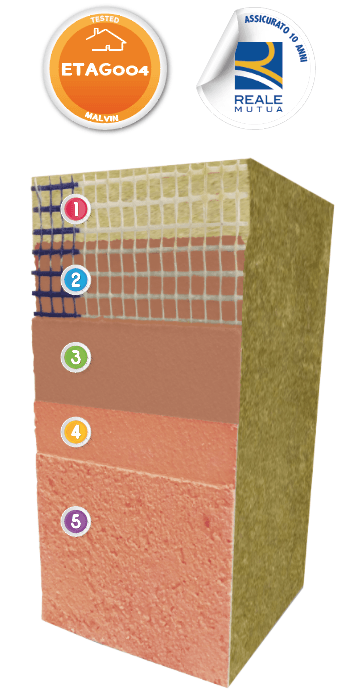

Coat system with rock wool sheetFibrangeo BP ETICS

System with fibre-panelled rock Fibrangeo BP ETICS

Adhesive/Smoothing Natural hydraulic lime in NHL

Mineral decoration Acril-siloxane

Strengths

• Certified System

• System Insured 10 years

• Guaranteed Performance

• Durability

• Environmentally friendly

• Natural 100%

• Reduction of energy consumption

• Insulation from cold and heat

• Correction of thermal bridges

• High thermal and acoustic insulation

• High breathability

• Sound absorbing

• Good thermal inertia

• Energy Requalification

• Energy saving

• Thermo-Hygrometric Comfort

• Healthier and livable Environments

• Improvement of living comfort

• Ease and speed of application

1-Fibre sheet rock fibrangeo BP ETICS kPa ≥ 250-λ ≤ 0.011 W/MK

2-Glass Fibre reinforcement net ETAG 004

3-Intocalce CPP adhesive/rasante Natural Hydraulic lime (NHL)

4-Acrisil Primer coloured Acril-siloxane

5-Acrisil coloured mineral coating acril-Siloxane

Coat system with XPS Isolex extruded polystyrene Sheet

Cycle with panels XPS Isolex polystyrene Extruded Adhesive/cement-Smoothing Acrylic mineral decoration

Strengths

• Certified System

• System Insured 10 years

• Guaranteed Performance

• Durability

• Reduction of energy consumption

• Insulation from cold and heat

• Correction of thermal bridges

• High thermal and acoustic insulation

• Energy Requalification

• Energy saving

• Thermo-Hygrometric Comfort

• Healthier and livable Environments

• Improvement of living comfort

• Ease and speed of application

1-Isolex Extruded polystyrene plate kPa ≥ 250-λ ≤ 0.031 W/MK

2-Glass Fibre reinforcement net ETAG 004

3-Intocalce CPP adhesive/rasante Natural Hydraulic lime (NHL)

4-Acrisil Primer coloured Acril-siloxane

5-Acrisil coloured mineral coating acril-Siloxane