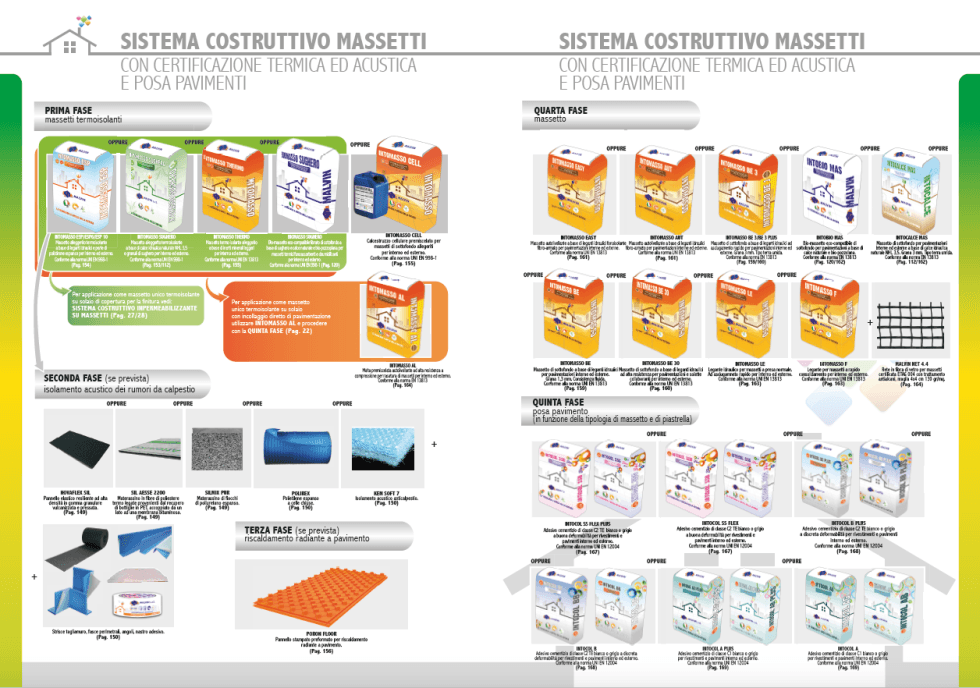

Thermo-Acoustic Screed System

THERMAL AND THERMO-ACOUSTIC CORRECTION OF HORIZONTAL OPAQUE SURFACES

Opaque horizontal surfaces and heat-insulating screeds

To achieve all the objectives indicated by the ID 26/06/15 "Minimum requirements", indicating minimum thermal performance values of buildings, great attention must be paid to making the right technical choices and using the right materials to obtain ideal thermal insulation. Achieving good thermal insulation is essential to obtain a good level of comfort and a consequent economical saving for the management of the winter heating and the summer cooling. Often, the thermal insulation of the opaque horizontal surfaces is very important, notwithstanding that, in a residential unit with a flat surface of 100 sqm, the horizontal opaque surfaces represent about 2/3 of the entire surface of the housing volume. It therefore represents a considerable part of the dispersal surface.

Roof Ceilings

Roof slabs are particularly important in the energy balance of the housing unit, as they constitute the largest dispersing surface to the outside. In order to adequately insulate the floors covering the buildings and to achieve effective thermal insulation, the prepackaged thermal insulating screeds can be used with high breathability and with remarkable ease of application. Packaging and laying are the same as traditional screed, except that prepackaged thermal insulation screed includes light aggregates with particular characteristics and natural additives that facilitate installation and guarantee correct adhesion on any type of support; they control withdrawal and ensure a slow and optimal maturation. The use of thermal insulating screeds allows, with the use of only one material, the user to configure the slopes and to lay the tiles and/or cement and/or bituminous sheaths, guaranteeing thermal insulation of the floor. Thanks to the ease of modelling fresh thermal insulating screeds, one can follow the outlines of cavities and/or roughness of the horizontal surfaces to be isolated. A thermal insulation operation with prepackaged thermal insulation screeds is preferable to that performed with plastic sheets (EPS, XPS, etc.), as the latter forms a barrier to the natural passage of water vapour. There is another aspect to consider and that is heating by direct radiation; Often we plan while only thinking about the thermal insulation in winter and summer: creating a thermal insulation with plastic materials with high thermal performance. While this solution is excellent for winter and summer environmental insulation, thanks to the low conductivity of the material, but often neglects thermal inertia; a property which is virtually absent in this type of materials that prevents thermal displacement for at least 8/10 hours - a feature that ensures the non-heating of indoor environments, with considerable discomfort for occupants and higher costs for summer cooling. The use of thermal insulating screeds allows, with the use of only one material, to guarantee thermal insulation of the floor and, thanks to a mass considerably higher than that of plastic materials (400kg/MC versus 10/20kg/MC), a remarkable increase in the overall thermal inertia of the slab, thus an increase in displacement resulting in an improvement of insulation.

Intermediate floors

We must not forget the thermal insulation of opaque horizontal surfaces (floors and ceilings) of the single real estate units bordering on unheated environments, where the regulation imposes a transmittance value U ≤ 0, 80w/m2 K. The opaque horizontal surfaces (floors and floor) of single real estate units bordering on other units, represent about 2/3 of the entire surface of housing volume, thus representing a considerable part of the dispersion surfaces. In addition, special conditions may occur which increase the dispersion, such as the non-heating of the upper or lower bordering unit (unrented periods, daytime offices, presence of commuters, etc.). This would cause a worsening of living conditions and a burden of cost due to dispersions through unheated environments through a large surface. Therefore the use of a thermoinsulating screed also has a considerable benefit in terms of reduction of dispersions towards the lower and upper housing units (reduction of dispersions exceeding 40% between the realization of the same thickness of Thermal insulation screed compared to a traditional screed). The lightness characteristics of thermoinsulating screed in the structural design of new buildings and the renovation of old buildings are not to be underestimated.

In addition to the thermal insulation there is the advantage of having a material that does not constitute an element of further burden of weight on the structures compared to the conventional materials. A thermal insulation operation with prepackaged thermal insulation screed is preferable to those carried out with cellular screeds or lightweight screeds packaged on-site. Prepackaged thermoinsulating screed guarantee, certified λ values: reliable transmittance values, consistency of the mixture and therefore of thermal insulating performances, constancy of mechanical performances, controlled retreats and durability. All this is possible thanks to the monitoring and constancy of the raw materials used and to automated and precise production processes. Features certainly not guaranteed by the cellular screed or lightweight scree packaged in the yard as they are subject to the variances of the raw materials used and packaging processes which are often manually approximated, which does not guarantee accuracy, thus leaving too many margins of error and therefore ineffective and uncertificable performances. Another advantage of these screeds is in the Thermo/acoustic package, where the thermal insulation screed in addition to its thermal function, is put into work on the raw slab for the regularisation of a planar surface suitable for the reception of the next sound-absorbing mat and successive screed and paving floors.

Opaque horizontal surfaces and acoustic correction

The acoustic correction of the opaque horizontal surfaces of the civil buildings has now become a necessity for achieving the best living comfort. The D.P.C. M. 5/12/1997 implementing decree of the Framework Law on noise pollution defines the requirements for minimum acoustic performance, horizontal opaque surfaces, for civil buildings of all kinds. These minimum acoustic performances are obtained with the use of soundproof insulating mats of various kinds (vulcanised granular rubber, thermo-bonded polyester fibres, expanded polyurethane, closed cell polyethylene, laminates, etc.) and thickness, in function of the typology of the ceilings, of the acoustic values to be reached and according to the intended use of the civil buildings. Malvin offers a series of specific acoustic mats for every need. They will then be covered with finishing screed and subsequent gluing of floors (with a minimum weight on the mat of at least 115kg/sq m).

Construction systems and Living comfort

Malvin has worked in this arena through experimentation and the creation of innovative and specific constructive systems. Malvin offers a new range of products, born from studies and experimentation in our research and development laboratories and from direct experiences in the yard, for the realization of screeds not only of high quality and durability, but also of easy and fast application. The support of a partner, a leader in the field of acoustic insulation, has allowed to develop a series of intervention packages that includes the insertion of deadening material that, combined with screeds, allows the attainment of the requirements imposed by the regulations. For the attainment of the best living comfort and the respect of the values imposed by the regulations regulating the thermal insulation ID 26/06/15 "Minimum Requirements" and the acoustic insulation law 447/95 and D.P.C.M. 5/12/1997, the "Thermo-Acoustic Screeti System" is born which provides a series of innovative, safe and durable constructive solutions.

Intomasso sughero

Eco-compatible Bio-mortar certified, lightened, fibered with a special composition of polypropylene fibres specially studied, based on natural raw materials such as cork granules and natural hydraulic lime according to EN 459-1 for Screeds of Heat-insulating, sound-absorbing and dehumidifiers. to be applied directly on any internal and external surface, provided that it is stable and not subject to capillary ascent, suitable to receive the subsequent application of any type of screed, even With the interposition of mat for the acoustic insulation of the noise, to be applied on slabs, flat and inclined roofs, terraces, also for the formation of slopes, for light filling and drowning of the plants on the floor, etc. To be applied with plastered machine, continuous mixer, mixer by glass or by hand. The characteristics of the natural hydraulic lime are such as to guarantee a very slow and constant hardening that allows to obtain thermal insulating screes with high durability and breathability. It does not form barriers to steam and does not contain solvents. Recyclable as inert at the end of life.

Packaging: 50 lt sacks-55 sacks Footboards

Usage: Indoor/outdoor

Colour: Hazelnut granulometry: ≤ 3 mm

Yield: 1 bag for 1 sqm thickness 4 cm

Vapour resistance coefficient en 1015-19: μ ≤ 5 capillary water absorption en 1015-18: Class "W0"

Specific Heat EN 1745:1.00 kj/kg K

Certified Thermal conductivity: λ = 0.068 W/MK *

Compression resistance at 28 days EN 1015-11:2 N/mm2 (CSI)

Specific weight dry mortar: 400 Kg/MC

* Certification: Certificate Institute LAPI S.p.A. N ° 366.2 DC 0050/12

Intomasso ESP

Lightweight premixed screed, certified, based on hydraulic binders and expanded polystyrene beads, with compensated shrinkage and controlled drying, ideal for the hand-or machine-making of heat-insulating substrate screed, to be applied directly on any internal and external surface as long as it is stable and not subject to capillary ascent, suitable to receive the subsequent application of any type of screed even with the interposition of mat for sound insulation of noises from Trampling, suitable for the thermal insulation of roofs etc. To be applied with plasterer machine, continuous mixer, mixer by glass or by hand. It does not form barriers to steam and does not contain solvents.

Packaging: 50 lt sacks-55 sacks Footboards

Usage: Indoor/outdoor

Color: Grey

Particle size: ≤ 5 mm

Yield: 1 bag for 1 sqm thickness 4 cm

Vapour flow resistance coefficient EN 1015-19: μ ≤ 9 certified thermal conductivity: λ = 0.0762 W/MK *

Compression resistance at 28 days EN 1015-11:1.5 N/mm2 (CSI)

Specific weight dry mortar: 400 Kg/MC

* Certification: Certificate Institute Giordano n ° 281240 of 18/04/2011to LAPI S.p.A. N ° 366.2 DC 0050/12

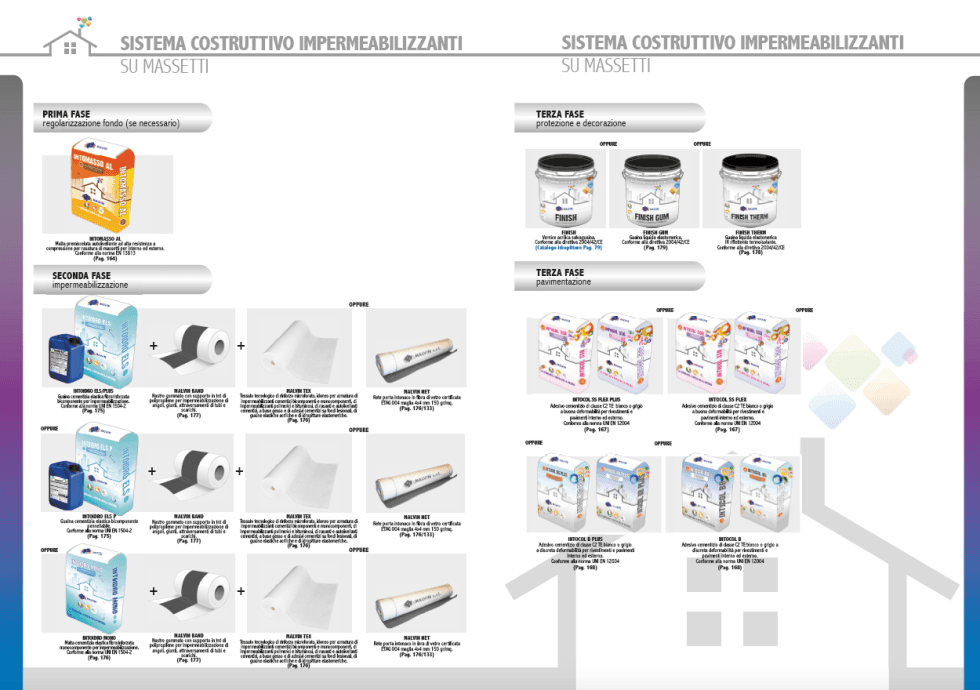

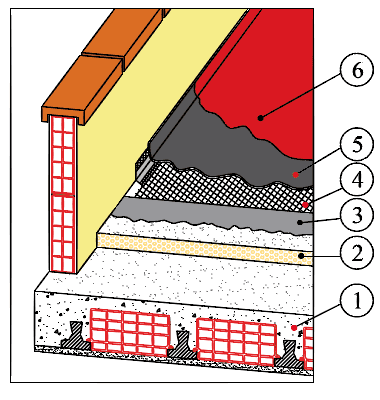

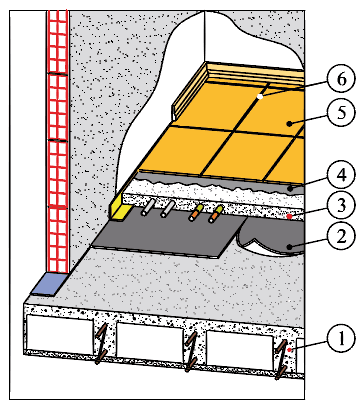

Thermal insulation screed system with bicomponent cementitious waterproofing

6- (FINISH)

5- Bicomponent cementitious Sheath(INTOIDRO ELS)

4-HIGH TECH Reinforcement System 0 plaster holder in fibreglass certified ETAG 004 Mesh 5x5 mm from 160 gr/MQ

3-Low-thickness level (AL Intomasso)

2-Thermal insulation screed

1-Concrete covering floor

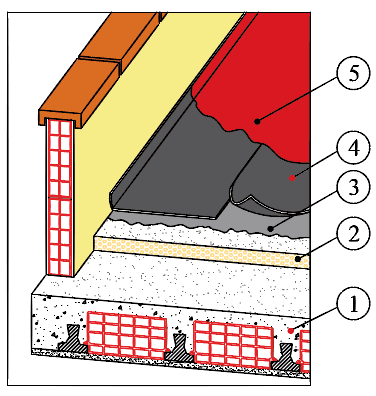

THERMO-INSULATING SCREED SYSTEM WITH BITUMINOUS WATERPROOF SHEATH

5-Protective sheath (FINISH)

4-Waterproof bituminous sheath

3-level low thickness (AL Intomasso)

2-Thermal insulation screed

1-Roof slab in Lateran cement

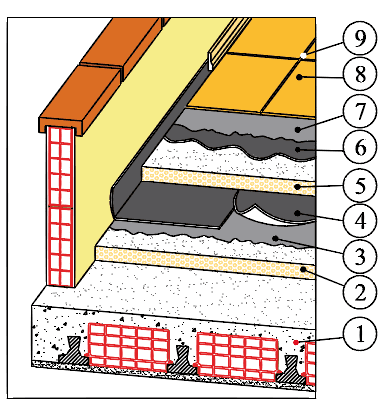

THERMOISOLATING SCREED SYSTEM WITH PAVEMENT

9-Intoleak

8-Flooring

7-Glue

6-cementitious bicomponent sheath (Intoidro ELS)

5-Thermal insulation screed

4-Waterproof bituminous sheath

3-level low thickness (AL Intomasso)

2-Thermal insulation screed

1-Roof slab in Lateran cement

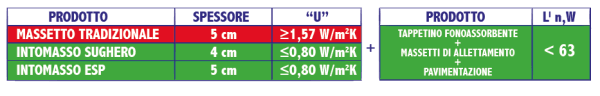

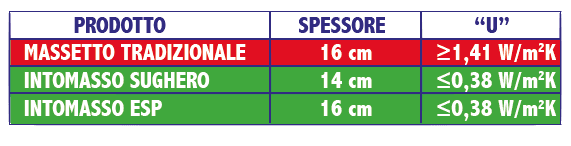

EXAMPLES OF “U” TRANSMISSION through floor covered in 20 + 4 cm thick Lateran cement

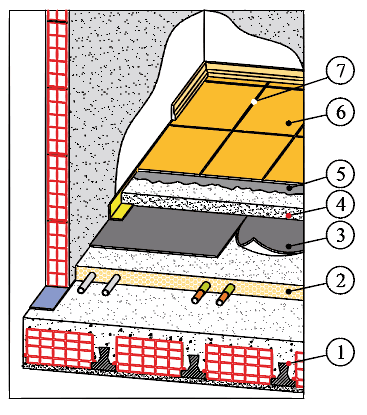

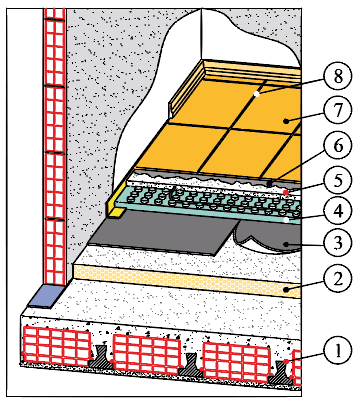

THERMOACOUSTIC SCREED SYSTEM

7- INTOFUGHI

6- FLOORING

5- NECKLACES

4- ALLOWMENT PLAN

3- SOUNDPROOF TAPER

2- THERMO-INSULATING SCREED

1- LATERAN CEMENT BRIDGE

Acoustic screed system on lightweight heat-insulating slabs

6-Intoleak

5-Flooring

4-gluing

3-Entrapment Screed

2-Sound Insulation mat

1-Floor heating insulation

THERMOISOLATING SCREED WITH PAVEMENT

8-

Intoleak

7-Flooring

6-gluing

5-Entrapment Screed

4-printed panel for floor heating

3-Sound Insulation mat

2-Thermal insulation screed

1-Floor slab in Lateran concrete

Example of 'U' transmittance values and noise reduction from footsteps on an intermediate floor with 20 + 4 cm thick cement